source : SENWART Author : Senwart Time : 25-7-2024

Chainsaw power for 2 stroke, single-cylinder, forced air-cooled gasoline engine, through the gasoline engine output mechanical power, drive the saw chain along the guide plate to stop high-speed operation of the cutting force, and then complete the sawing task.

First, the structure of the chainsaw components mainly crank linkage mechanism, crankcase and cylinder, ignition system, oil supply system, intake and exhaust system, smoothing system, cooling system, starting device. Cylinder, including the inner wall, heat sink, extinguishing chamber, etc., there are three holes on the cylinder, namely, intake holes, exhaust holes and gas exchange holes, these three holes are identified at a certain moment by the piston closed.

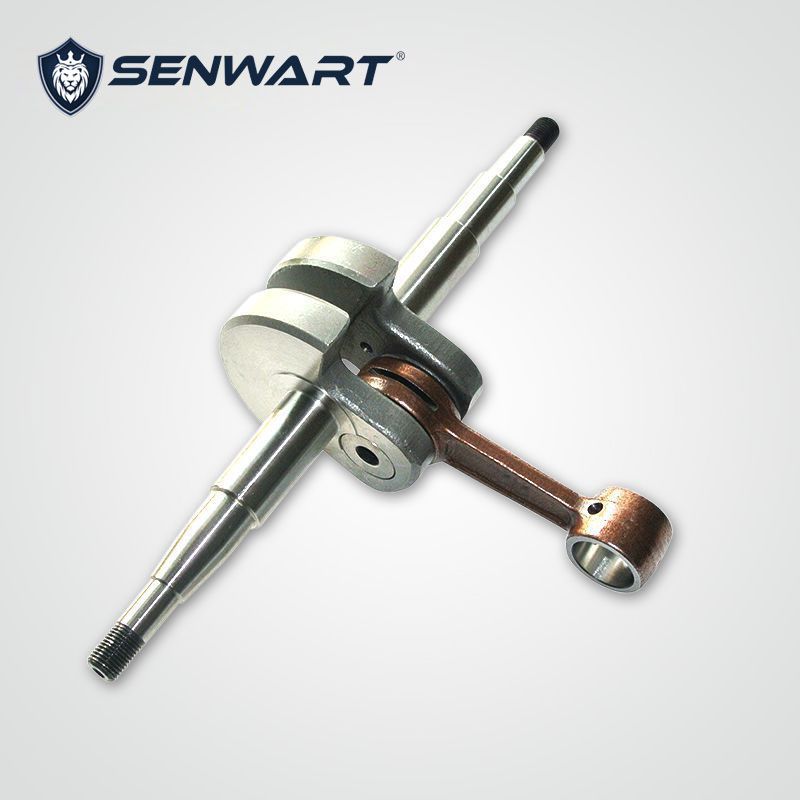

The complete sealing of the cylinder is to realize the necessary conditions for the chain saw to continue to operate and generate power. Cylinder mounted on the crankcase. The piston can reciprocate in the cylinder and block the cylinder from the lower part of the cylinder, forming a sealed space. Fuel is extinguished in the sealed space, and the power generated pushes the piston to move. The reciprocating motion of the piston pushes the crankshaft through the connecting rod for rotary motion, and the crankshaft then outputs the power from the flywheel end. By the piston group, connecting rod, crankshaft and flywheel composed of crank linkage mechanism, which is the main part of the chainsaw to transfer power.

Piston group consists of pistons, piston rings, piston pins and other components. Piston is cylindrical, equipped with piston rings below, by means of reciprocating movement in the piston closed cylinder, to avoid leakage of gas in the cylinder. Piston pin is cylindrical, it penetrates the pin hole in the piston and connecting rod small head end, the piston and connecting rod connected. The connecting rod is divided into three parts: the big head end, the small head end and the rod body. The big head end is connected to the crank pin of the crankshaft, and the small head end is connected to the piston pin. When the connecting rod task, the small head end with the piston for reciprocating motion, the big head end with the crank pin around the crankshaft axis for rotary motion, the rod body for complex rocking motion.

The role of the crankshaft is to convert the reciprocating motion of the piston into rotary motion, and the work done by the contraction of the stroke, through the flywheel mounted on the rear end of the crankshaft to transfer out. The flywheel stores energy to allow the rest of the piston's stroke to do its job properly and to rotate the crankshaft evenly. The intake and exhaust system usually consists of an air filter, intake pipe, exhaust pipe, and muffler. In order to supply fuel to the cylinders, chain saws have an oil supply system. Through the carburetor installed at the inlet end of the intake pipe will be air and fuel, according to a certain concentration of mixing, and then supplied into the cylinder through the intake pipe, by the chainsaw ignition system controlled by the electric spark timed to extinguish.

Chainsaw cylinder fuel in the extinguished, so that the piston, cylinder and other parts of the heat, its temperature rises. In order to ensure the normal operation of the chainsaw, so that the piston, cylinder and other parts are not damaged due to overheating, there must be a cooling system. Flywheel blade and by the starter cover, shell and other parts of the formation of the wind channel, composed of chainsaw cooling system. Chain saws can not be transferred from the parking state into the running state by itself, must be an external force to turn the crankshaft, make it start. This external force occurs in the device is called the starting device.

Second, the principle of the task of the chain saw for the continuation of the task of the chain saw, the piston must be pushed to the crankshaft back to the original position in order to push the crankshaft again, which requires the piston can be in the cylinder to do reciprocating motion.

Piston movement from one end of the cylinder to the other end of the cylinder, called a stroke. The task cycle of the chainsaw is composed of processes such as intake, compression, quenching and contraction, and exhaust. The first stroke: the piston moves upward from the lower stop, the intake hole, exhaust hole and gas exchange hole on the cylinder is closed at the same time, the mixture into the cylinder is compressed; the piston continues to move upward, further compression of the mixture, the intake hole will be exposed with the piston upward, the combustible mixture at this time by the piston below the flow into the crankcase.

The second stroke: the piston compression to the upper stop near, the spark plug just jump fire, extinguish the combustible mixture, gas contraction to push the piston down to work. As the piston moves down, the inlet hole is closed, sealed in the crankcase combustible mixture is compressed; when the piston is close to the lower stop point when the exhaust hole is open, the exhaust gas due to the weak pressure and rushed out; followed by the gas exchange hole is open, by the pre-pressurized combustible mixture through the gas exchange channel rushed into the cylinder, drive out the exhaust gas, stop the gas exchange process. Chainsaw exhaust process and air intake process is collectively referred to as the gas exchange process, the role of gas exchange is the last cycle of exhaust gas clean, so that the cycle into the fresh gas, in order to maximize the ability of the fuel in the cylinder completely quenched, so that the chainsaw to reach a greater power. The good and bad of the gas exchange process directly affects the use of chain saws, we should reduce the activity resistance of the intake and exhaust system, so you need to liquidate the channel of carbon and clean the air filter on a regular basis.